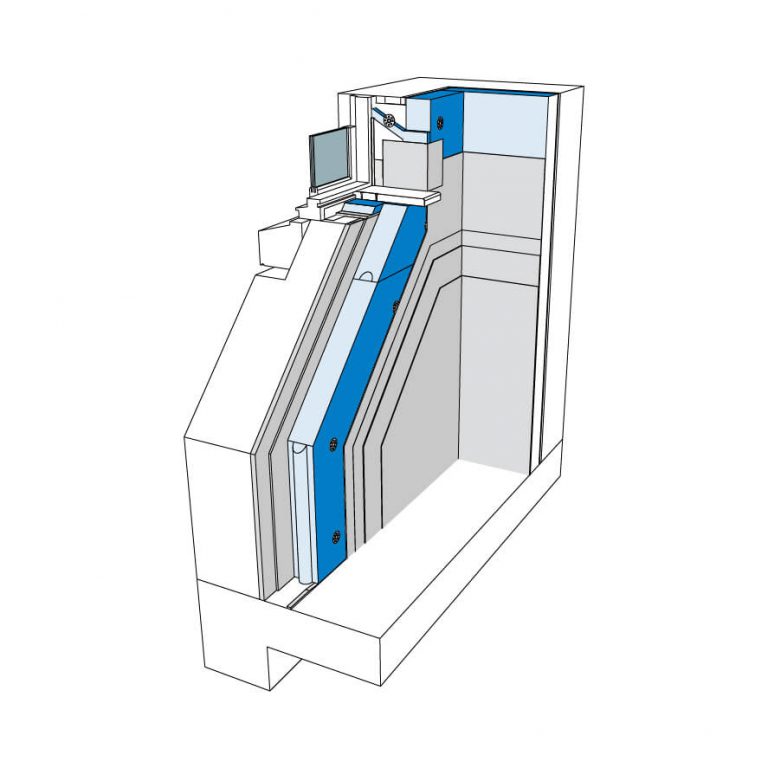

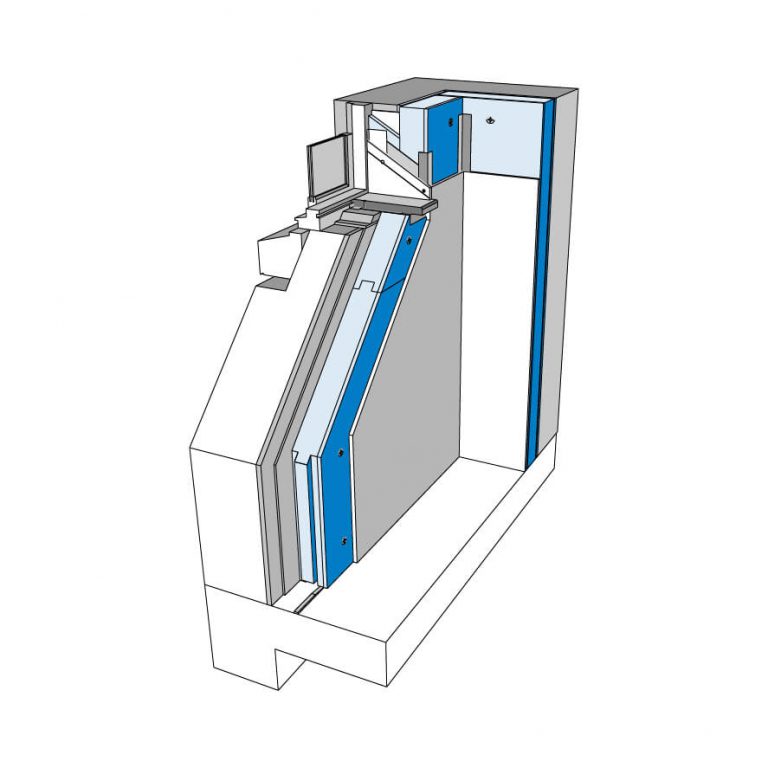

Lime Plastered Finish

Lime plaster directly onto the insulation board for a beautiful vapour open build up that achieves excellent airtightness and further improved climate regulation internally.

The best option for historic vapour open monolithic constructions where it is not possible to insulate externally and not appropriate to use vapour closed insulation systems.

click here