2 Bed Self-Build, Shipson-on-Stour

This purpose built, bespoke home was Constructed to Passivhaus standards giving the occupants low running costs in a sustainable way. The 2 bedroom 1.5 storey bungalow is located among the hills of the Cotswolds and is fully in keeping with it’s natural surroundings. The home has been built on land owned by the family of the occupants.

The idea from the owners was to build a home from scratch which took into placed importance not only the performance of the insulation system, but also sustainability, which is something we at Unity Lime are passionate about. Wherever it was possible, they wanted to ensure that natural/sustainable materials were used throughout the build and also that environmental impact was kept to the minimum level possible throughout the build.

A Sustainable Build for Natural Surroundings

Known as ‘The Paddock’ – this self-build property is based on a timber frame structure and features 2 bedrooms and 2 bathrooms and a sensational double height open plan living space. Thermal performance and airtightness requirements of the standard have been exceeded. The end result is a modest, (but still highly impressive) home which is comfortable and requires the minimum amount of both cooling and heating throughout the year.

As mentioned above, the property achieves Passivhaus standards, although due to the costs involved the owners decided not to get it officially certified as such.

Preventing Thermal Bridging

A ‘thermal bridge-free’ external envelope across the walls and roof was achieved by the contractor by using a continuous layer of 100mm Pavatex Isolair across the external areas of the building. Along with Isolair boards the build up also includes sheep wool insulation, which is a fantastic insulator and totally natural!

The external render was directly applied onto the uninterrupted layer of tongue and groove Isolair boards that cover the exterior of the property. The interior was finished with OSB board, concealing the 160mm stud wall and sheep wool insulation within, then plastered and painted.

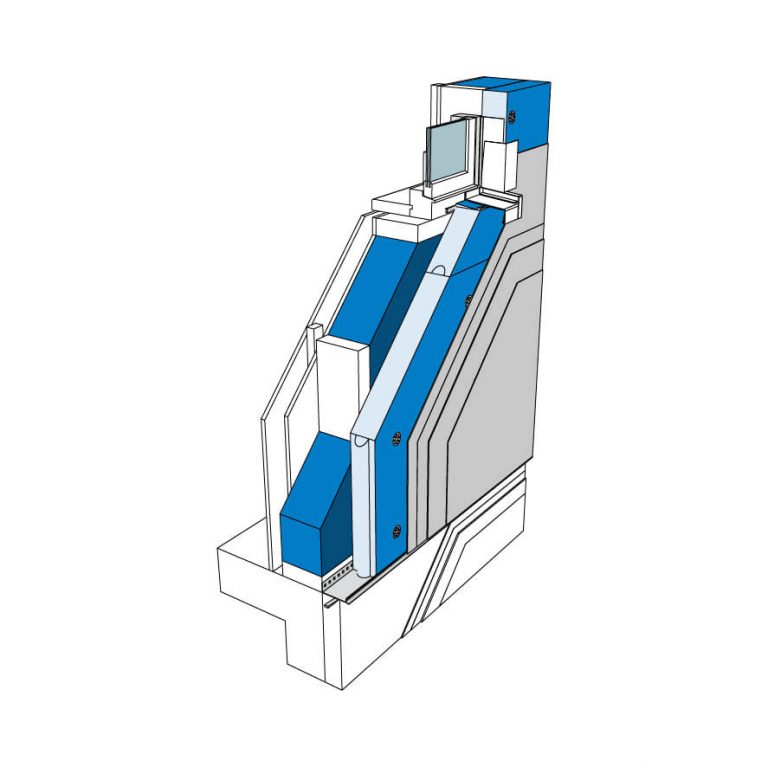

The hardwood framed, triple glazed windows were installed in such a way that thermal performance was maintained as the air leakage and thermal bridging will most often occur where 2 elements of the build up meet, in this case the junctions between the window elements and the layer of wood fibre. A 40mm over- lap of Isolair wood fibre insulation was factored in around each window space. This meant the windows were then installed from the inside of the property and thus each window was designed to be free of thermal bridging.

A Consistent Internal Temperature – Whatever the Weather!

The use of the wood fibre insulation means that not only are heating costs kept to an absolute minimum in the winter months, but one other aspect which isn’t talked about as much is the internal temperature in the hottest months of the year. Unlike many other types of insulation, Pavatex wood fibre uses it’s thermal mass capacity to store and slowly release heat across each 24 hour period. In practice this means that rather than super high peaks of temperature in the afternoon on a hot day, the temperature is kept to a much more consistent level throughout the day and night and makes a huge difference to comfort levels throughout the whole year.