CLT Project Buckinghamshire

Cross Laminated Timber (CLT) is an innovative wood building material that is becoming more popular in recent years due to its environmental and structural benefits. It is a type of mass timber construction made by gluing together multiple layers of timber at right angles to each other. This creates a solid wood panel with exceptional strength, dimensional stability, and fire resistance properties.

One of the major benefits of CLT construction is that the internal face of the board can be left exposed providing a beautiful appearance. Additionally, CLT is a carbon-neutral product as it stores carbon during its lifespan and can be easily recycled or repurposed at the end of its useful life.

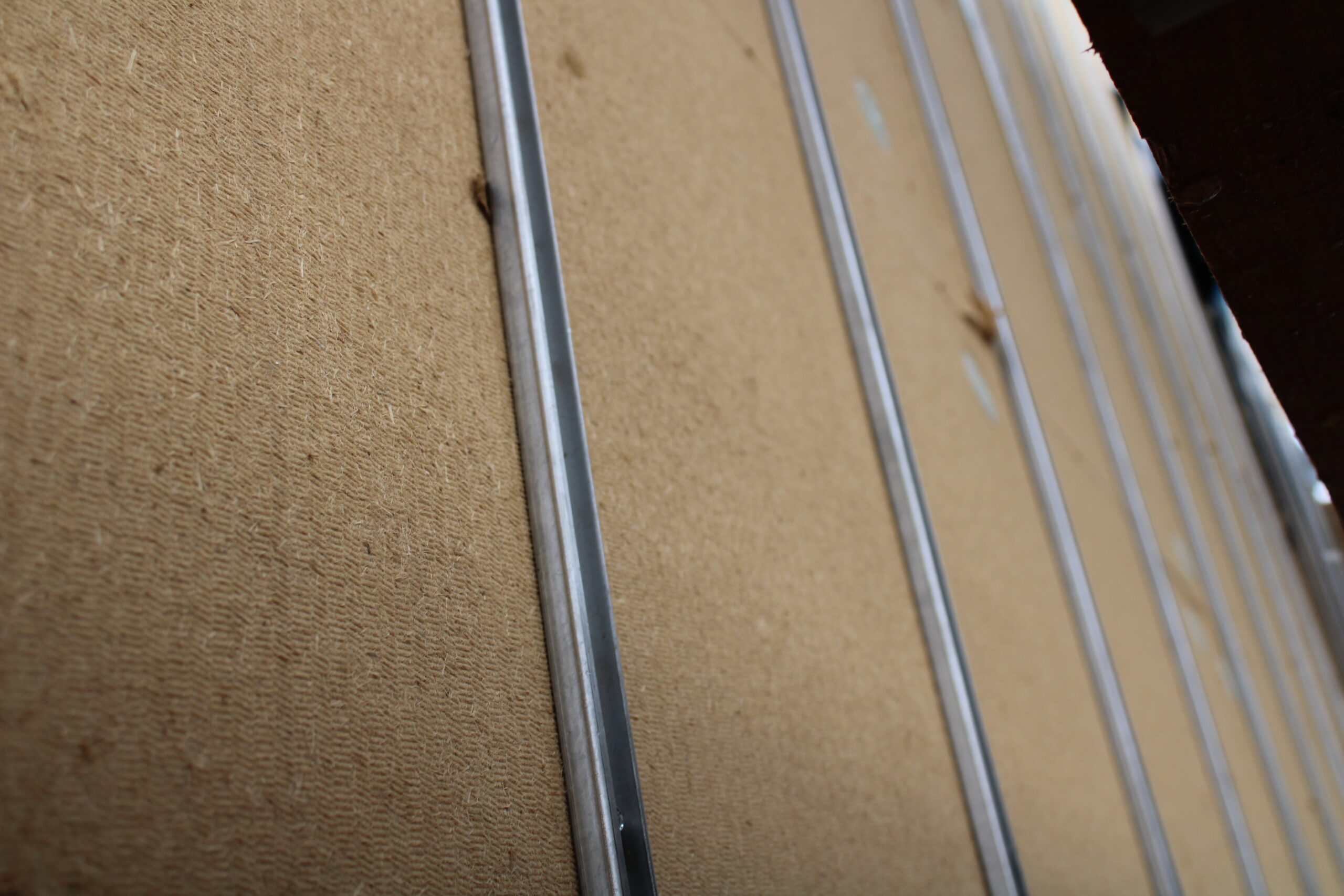

A DSB 2 airtightness membrane was installed over the external face of the CLT to provide exceptional airtightness. Over this a build up of PAVATHERM & ISOLAIR woodfibre insulation has been used the achieve exceptional thermal performance. As well as being sustainable and vapour open. The Isolair system is also BBA approved to not require an additional breather membrane over the external face of the boards. This reduces material and labour costs whilst assuring the homeowner that the system is robust.

A rail and tie system has been installed over the insulation to allow for a brick clad finish. This innovative system is a simple way to achieve traditional brick clad finishes whilst avoiding excessive thermal bridging by fixing each tie back to the substrate.

Ventilation is a crucial part of any breathable insulation system as it allows moisture to escape the build up. A minimum of 50mm of ventilation space should be allowed for when installing the brick façade – breather bricks & weep vents should be used. It is very important that the cavity is kept clear of mortar to prevent thermal bridges and blocking the ventilation zone.

The fantastic project is an excellent example of the carbon locking capabilities of wood and the impact it can have on creating a low carbon home.